You are here

Back to topStePacPPC Experts Demonstrate Value of MAP Technology in IFPA Webinar

In a recent webinar hosted by the International Fresh Produce Association, industry leaders came together to examine the science and proven success of modified atmosphere packaging, a pivotal technology that is transforming the global fresh produce supply chain. Featuring two experts from StePacPPC, the session offered a deep dive into how controlled packaging environments are helping to solve postharvest challenges, reduce waste and expand access to distant markets.

The Living Challenge: A Race Against Time After Harvest

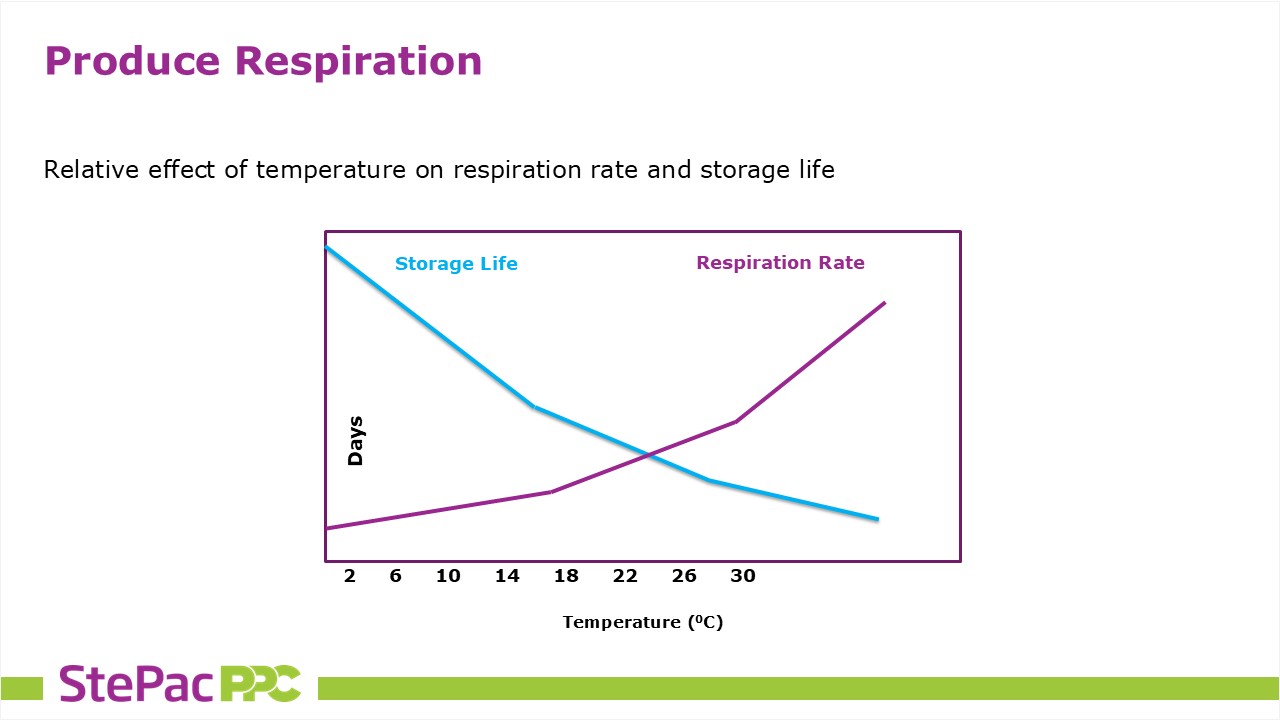

The webinar began with an important reminder from Dr. Gary Ward, chief technology officer at StePacPPC, who noted that fruits and vegetables continue to respire after harvest, consuming oxygen and releasing carbon dioxide and heat, which naturally accelerates deterioration.

Ivo Tunchel from StePacPPC’s Global Business Development team added that the rate of deterioration is largely determined by the rate of respiration and emphasized that temperature control is the most critical factor in slowing this process.

However, respiration is only one part of the postharvest challenge. Fresh produce is also affected by moisture loss, disease pressure and sensitivity to ethylene, making long-distance transport and extended storage especially challenging. MAP technology seeks to balance these biological and environmental factors, creating conditions that help maintain quality and prolong shelf life throughout the supply chain.

The Science of Preservation: More Than Just a Bag

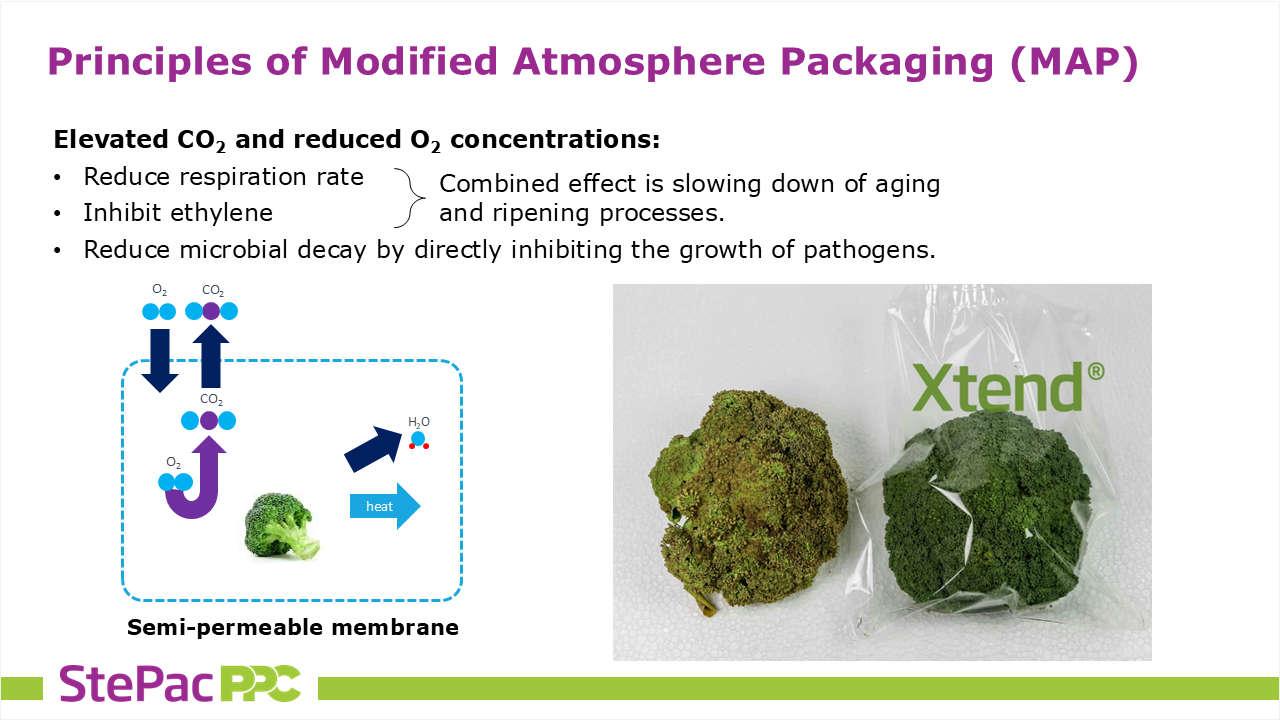

MAP technology provides an innovative solution by precisely controlling the gaseous environment inside packaging. By lowering oxygen levels and increasing carbon dioxide, MAP offers a threefold advantage: it slows respiration, inhibits ethylene activity and directly suppresses microbial growth. Together, these effects significantly delay aging and ripening and extend shelf life.

The two experts stressed that successful MAP is not a one-size-fits-all solution but a comprehensive systems approach. It requires high-quality produce, rapid cooling and a consistently maintained cold chain. Equally crucial is that the packaging itself be carefully engineered. Advanced films manage water vapor transmission and feature anti-fog properties, preventing dehydration and condensation without encouraging decay. At the same time, film permeability must be precisely matched to the respiration rate of the produce and the conditions of the supply chain in order to achieve the desired result.

According to Ward, StePacPPC employs high-performance polyamide-based films with enhanced water vapor transmission rates to optimize moisture management. When combined with laser-perforation technology, these films effectively regulate the internal gas composition, maximizing the overall performance of the MAP.

Proof in Performance: Case Studies From Chile to China

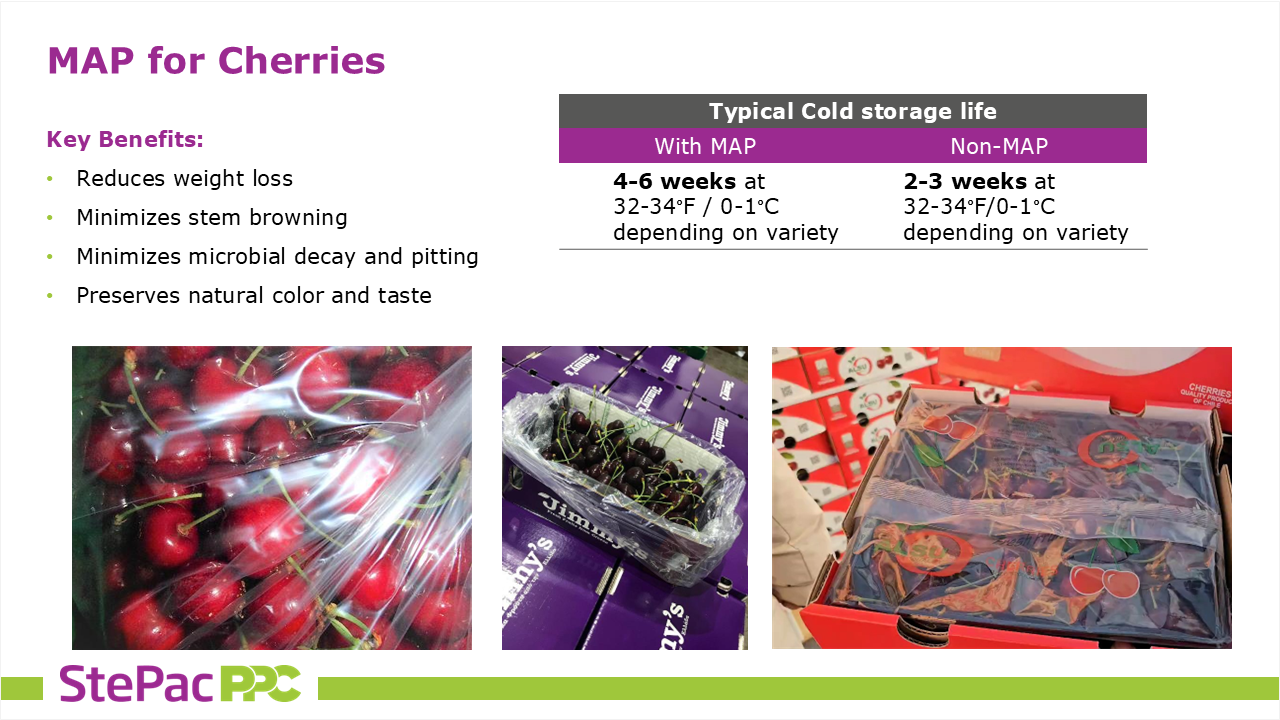

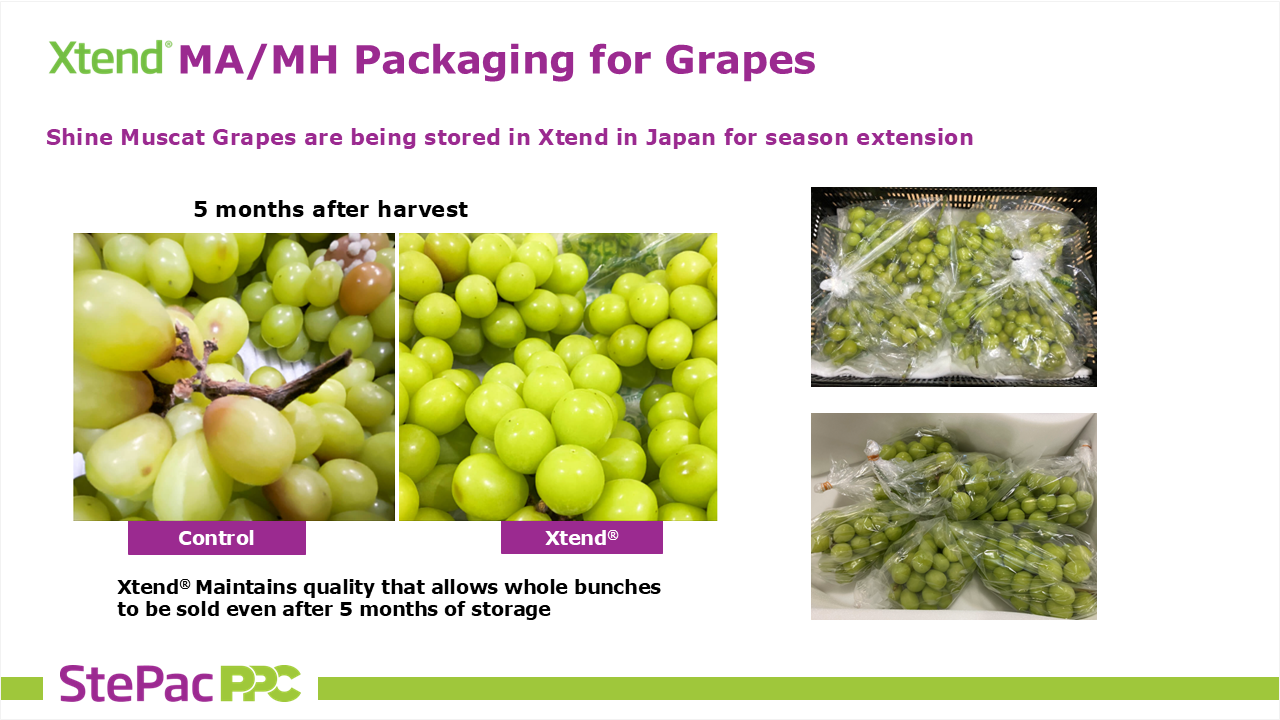

The webinar next moved from theory to tangible results, highlighting transformative improvements across key produce items. For blueberries, MAP combined with StePacPPC’s automated formats such as Xflow preserves natural bloom and quality for over 45 days while reducing plastic film use by 40%. In the case of broccoli, Xtend, StePacPPC’s modified atmosphere and humidity solution, eliminates the industry’s reliance on ice-filled polystyrene boxes, freeing up as much as 66% more container space per shipment. For cherries, StePacPPC’s MAP-based solutions double the shelf life to 4–6 weeks, making the 25-day sea journey from Chile to China commercially viable while maintaining stem freshness and firmness. Grapes also benefit: the Xtend solution extends the season for premium varieties such as Shine Muscat, preserving marketable quality for up to five months.

The webinar concluded with a lively Q&A session, reflecting the participants’ strong engagement and curiosity. Attendees posed questions not only about the featured crops but also about high-value fruits and vegetables such as turmeric root, avocados and sugar plums. Both Ward and Tunchel provided detailed answers, sharing practical insights and technical guidance. The dynamic discussion underscored the growing interest in innovative postharvest solutions and reinforced MAP’s role as a vital tool for preserving quality, reducing waste and expanding global market opportunities.

For further information, please contact:

Ms. Hila Nagel

Marketing Communications Manager at StePacPPC

Phone: +972-4-612-3500

Email: info@stepacppc.com

Web: www.stepacppc.com

Images: StePacPPC

This article was translated from Chinese. Read the original article.

Add new comment