You are here

Back to topEmerson Cargo Solutions Builds Smarter Cold Chain Management

Representatives from over 50 produce companies attended the Intelligent Cold Chain Management Salon held in Shanghai on 22 November by Emerson Cargo Solutions. With a theme of, “loss reduction, refined management, and fewer trade disputes,” participants praised the seminar as an informative event. It was held as part of China Green Week.

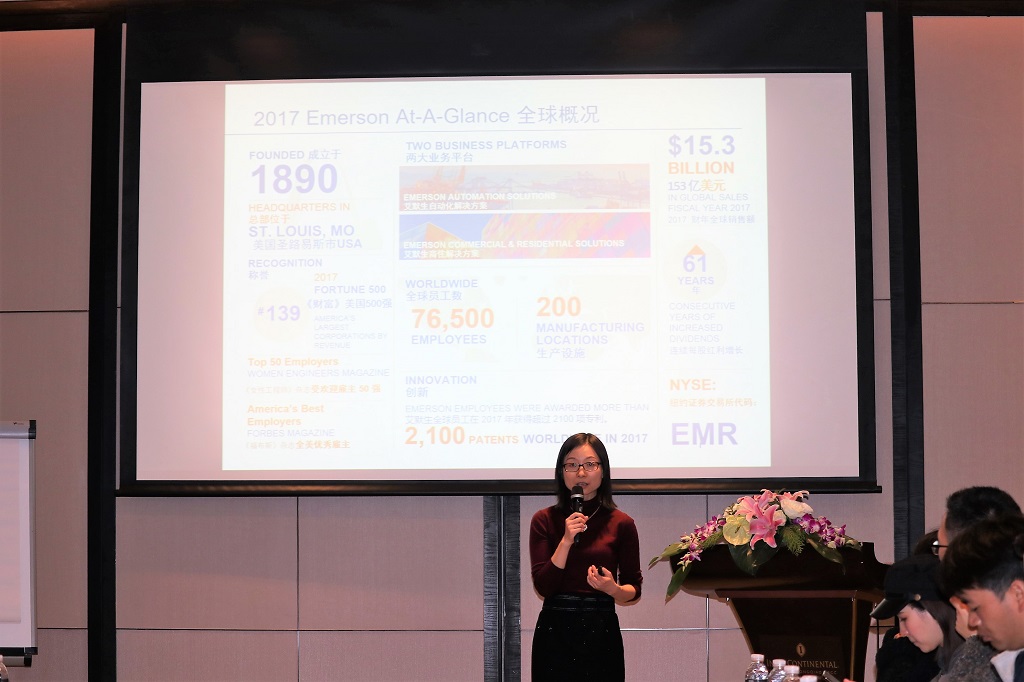

Ms. ZHOU Mi, Business Director of Cold Chain, Climate Technologies, Emerson Commercial and Residential Solutions, kicked things off with an introduction to Emerson’s history and its blueprint for developing the Chinese market. Emerson consists of two business platforms: Automation Solutions and Commercial & Residential Solutions. In the 2017 fiscal year, this venerable Fortune 500 firm boasted global sales totaling $15.3 billion, of which 21% came from Asia. China, where Emerson has maintained a strong presence for decades, has since 2002 been the second largest market for the company, after the United States.

▲Ms. ZHOU Mi, Business Director of Cold Chain, Climate Technologies, Emerson Commercial and Residential Solutions

As for Emerson’s motivation in venturing into cargo monitoring, Ivan Fullin, Director of Emerson Cargo Solutions–Asia, said food waste caused by complex supply chains has become a global problem. “One billion metric tons of food is lost or wasted, never making it from farm to fork,” he said. “One third of food produced each year is never eaten. Over 800 million people are chronically hungry.” Emerson firmly believes that the situation can be much better if food is monitored during transportation. Driven by this mission, the company has launched a new business unit called Cargo Solutions which provides logging and tracking solutions for products that are moving through the cold chain.

▲Mr. Ivan Fullin, Director of Emerson Cargo Solutions–Asia

Also invited to deliver speeches onstage, sharing their insights into the impact of temperature fluctuation on fruit quality were: Ms. Mabel Zhuang, Editor-in-Chief of Produce Report; Mr. Kurt Huang, General Manager of Shanghai Oheng Import and Export Company; Ms. HU Ping, General Manger–China of Fiesta Foods Mexico; Mr. HU Xian, General Manager of Shanghai Airipening Agriculture Technology Company; and Mr. Saw Tiang-Aik, Sales Manager, Emerson Commercial and Residential Solutions, Asia Pacific.

▲Representatives from over 50 produce companies attended the seminar

Mr. YU Hailin, Account Manager, Cargo Solutions, Emerson Commercial and Residential Solutions, elaborated on the significance of monitoring cargo temperature from harvest to the final consumer and how Emerson’s GO line of loggers and trackers help to guarantee unbroken cold chain distribution.

▲Mr. YU Hailin, Account Manager, Cargo Solutions, Emerson Commercial and Residential Solutions

A highlight of the seminar was two case studies of how real customers used Emerson solutions to identify and correct temperature issues during shipping. For example, overland shipping from Kashgar, Xinjiang Uygur Autonomous Region to Guangzhou, Guangdong Province is one of the longest and most complex transit lines in China. Such a long distance of over 5,000 kilometers often results in quality problems for fresh fruit. One shipper found drastic temperature swings along the leg from Xinjiang to Xi’an after receiving alerts delivered by a GO tracker, which monitors the real-time location and temperature of goods in transit. The shipper settled the matter in no time after making a call to the driver, who had turned off the truck’s refrigeration unit on the road.

In addition to ensuring food safety, Emerson’s monitoring solutions also help customers access and interpret data to make good decisions. Thanks to the outstanding performance of Emerson trackers, beyond finding a temperature abnormality in real time via mobile phone, another shipper even finished the ripening process in-transit. In a shipment of jackfruit from Vietnam to Shanghai, the shipper noted low ripeness levels after the first stage of the journey. In the second leg of shipment, the in-transit temperature was elevated to 16℃ with the intention to accelerate the ripening process. Upon arrival, most of the jackfruits were well-ripened—featuring strong fragrance, sweet taste, and crisp texture.

▲The salon was praised as an informative event

As a company always focusing on real scenarios in the produce industry and relying on innovation to gain a cutting edge, Emerson has recently launched three new products based on market demand, including:

① GO Real-Time CO₂ Tracker: Monitoring levels of CO₂ and providing real-time alerts as shipments of fresh produce moves through the supply chain

② GO Real-Time Secure Tracker: Using real-time GPS tracking technology to mitigate cargo theft and financial loss

③ GO Real-Time Flex: A multifunctional real-time tracker which monitors a wider range of parameters such as pulp temperature, ambient temperature, location, light, and humidity

Image Sources:Emerson

Add new comment