StePacPPC Showcases at AFL How Advanced Packaging Can Transform Fresh Produce Supply Chains [1]

Submitted by Jing Zang [2] on

During Asia Fruit Logistica [3] in Hong Kong this September, the pavilion of StePacPPC [4], a leading provider of fresh produce packaging solutions [5], drew considerable attention from visitors. Ivo Tunchel, the company’s head of global business development, was invited to deliver a presentation at the Business Forum, where he highlighted how StePacPPC’s patented technologies — advanced packaging often integrating automation — help address key challenges in the global fresh produce industry, particularly in trade with China.

With over 30 years of experience, Tunchel played an instrumental role in pioneering the development and implementation of solutions that facilitated sea shipments of Galia and cantaloupe melons from Brazil to Europe and white asparagus from Peru to Europe, as well as the automated bulk packing of Peruvian and Chilean blueberries and cherries for export to China.

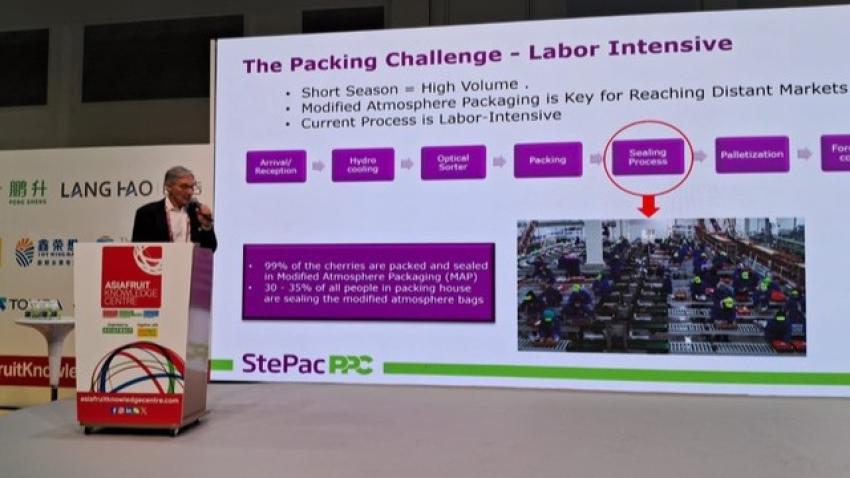

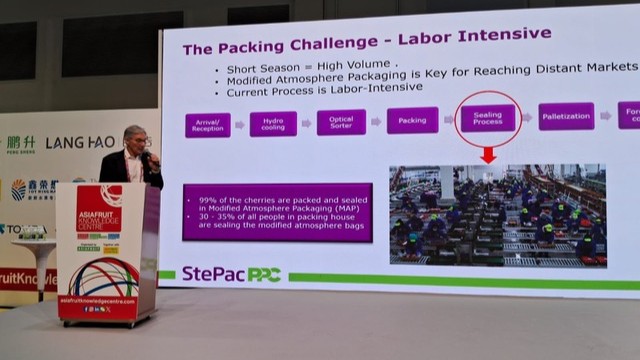

Using the cherry industry as an example, Tunchel outlined the challenges faced by Chilean exporters. Currently, up to 99% of Chilean cherries bound for China are packed using modified atmosphere packaging. This is a labor-intensive process in which 30–35% of packing plant staff seal bags manually, a practice that is increasingly difficult to sustain amid rising labor costs, creating a clear need for automation.

To address these challenges, StePacPPC has developed the Xflow automated packing system. The technology combines high-speed bulk packing with special films to reduce both labor and material use by up to 40% compared with manual methods. These films help create an optimal modified atmosphere that effectively slows cherry respiration, inhibits microbial growth and preserves quality. Importantly, the films also provide excellent condensation control and moisture management. This packaging is key to ensuring that Chilean cherries arrive in China fresh, even after more than 25 days at sea.

Tunchel’s insights were echoed by Dr. Gary Ward, StePacPPC’s chief technology officer, and Rani Kadosh, vice president of global sales and marketing, who were interviewed by Produce Report during the exhibition. According to Ward, the adoption of automated packing offers multiple benefits for the industry. Fully automated packing boosts operational efficiency by shortening the time from harvest to pre-cooling and packing, reducing labor requirements, and enabling packing houses to pack more high-margin 2–2.5 kilogram packages, which are highly sought after on the Chinese market. Moreover, automatic sealing ensures a consistent, attractive presentation while minimizing manual handling, further improving food safety.

When discussing the dynamic Chinese market, Kadosh noted that the approaches used in Chile could provide valuable lessons for China’s domestic fruit industry. Adopting automated systems and tailored packaging locally could help Chinese producers address supply chain challenges, boost efficiency and meet the growing consumer demand for high-quality fruit.

He told Produce Report that the strong traffic at the exhibition reflected how much the fresh produce market in Asia has advanced in recent years, with a high level of professionalism among both exhibitors and attendees. Kadosh also observed a growing awareness of the importance of proper postharvest handling and how modified atmosphere packaging can play a key role in preserving fresh produce quality along the supply chain. He noted that many Chinese importers receiving cherries in Xflow packaging regard it as a premium product, valued for its ability to retain freshness.

“Discussions at the event provided valuable insights into the challenges faced by producers within China and across Southeast Asia,” he added, “highlighting how technology and innovation can enhance fresh produce quality and reduce losses throughout the region.”

Images: © 2025 Produce Report

This article was translated from Chinese. Read the original article [6].